Order&Production Line Automation

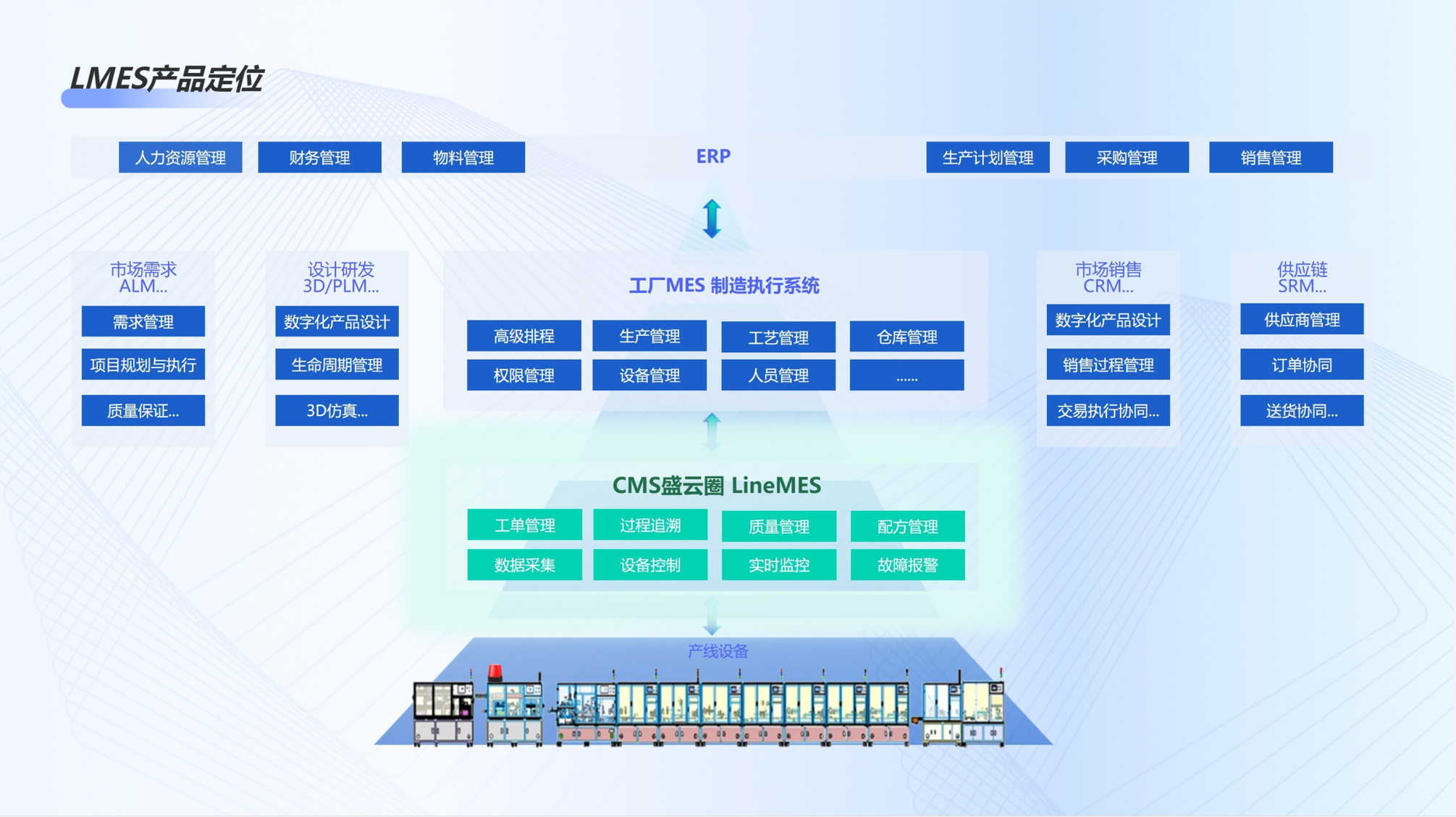

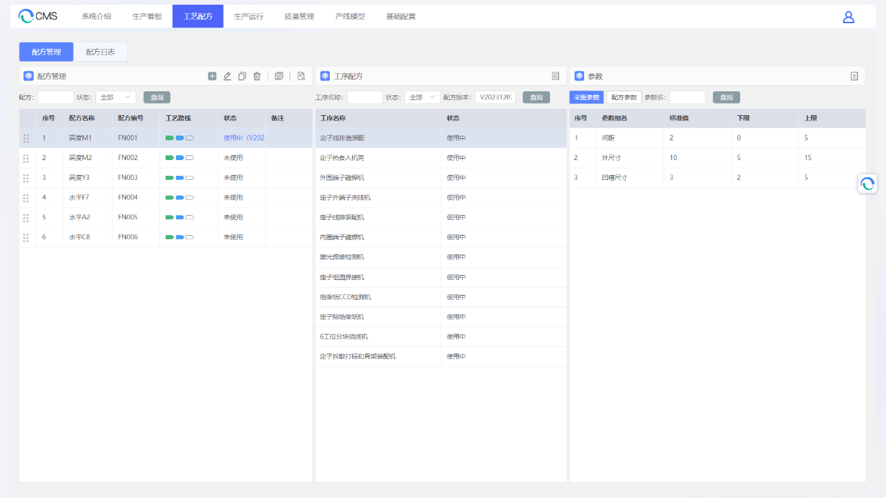

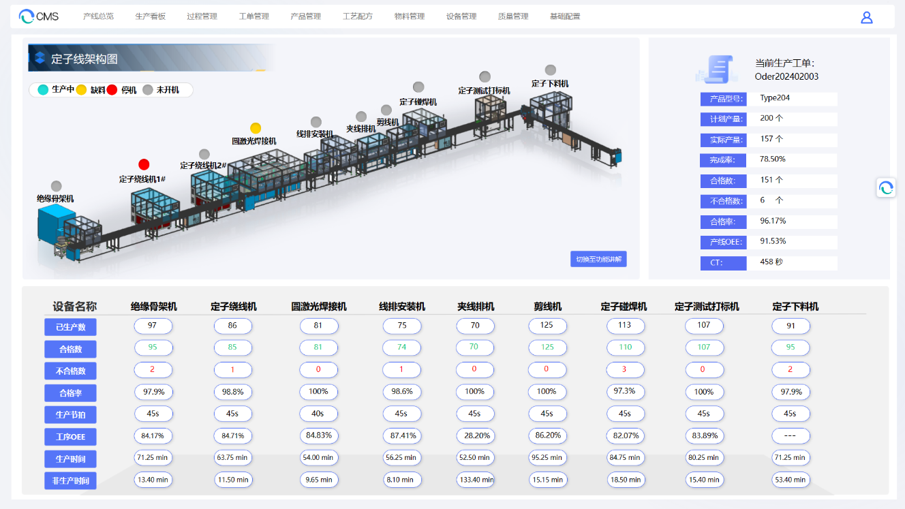

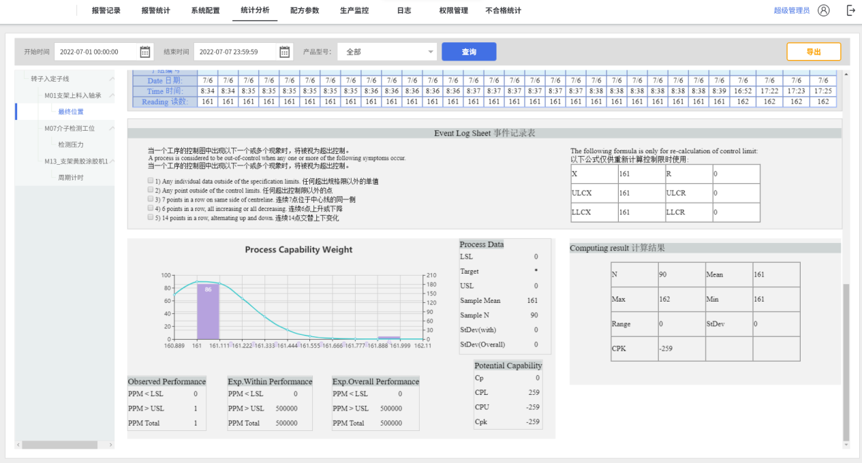

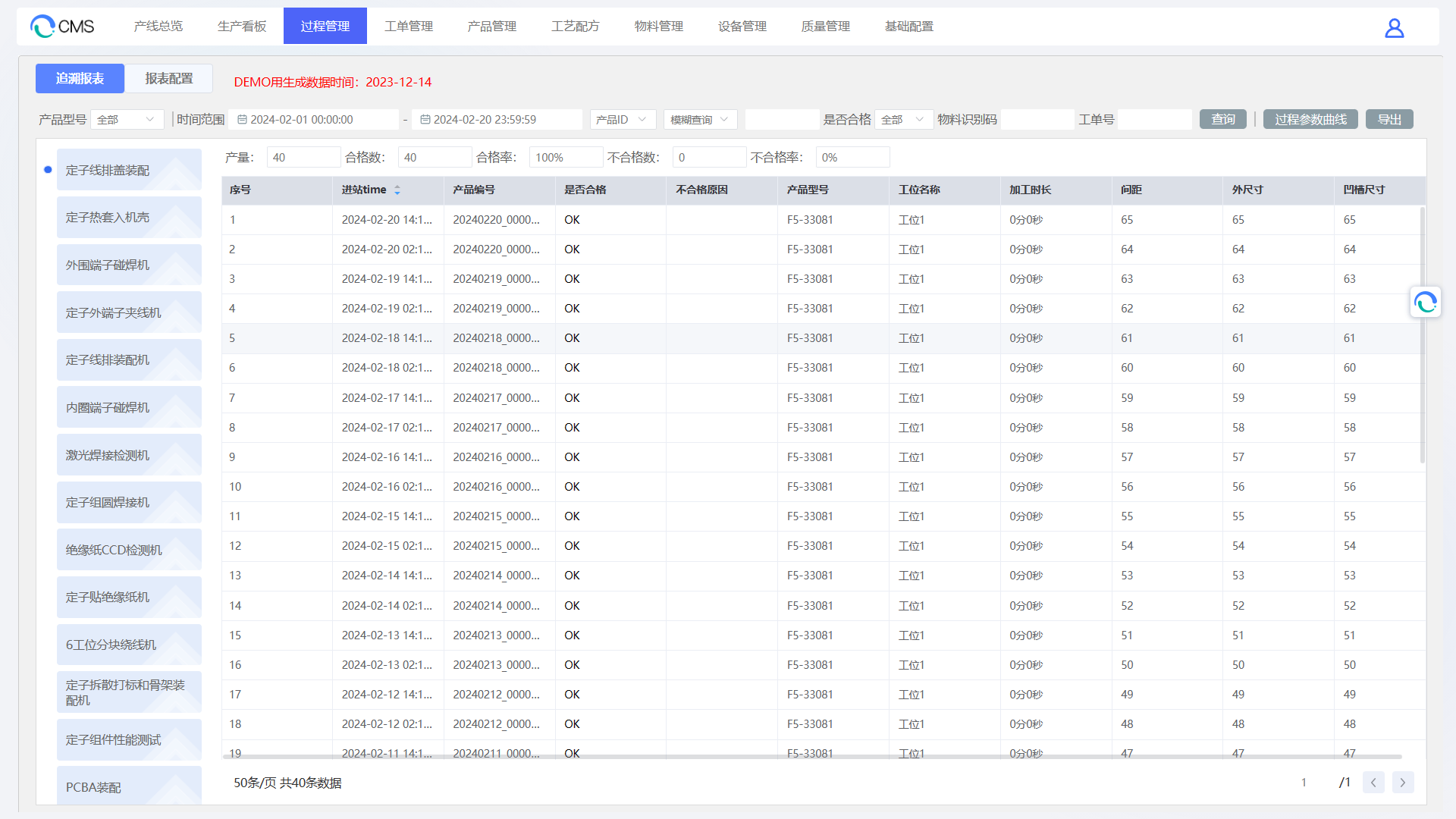

Directly interface with ERP/factory level MES system, real-time synchronization of orders and work orders, linked issuance of formulas, and one click issuance of orders and formulas. Reduce human factors, one click production reporting, improve efficiency, ensure accuracy, and reduce manual input costs.